Nidec Machinery's Technical Capabilities

As a manufacturer of FA equipment for automation and labor-saving systems, Nidec Machinery aims to develop unique products.

Nidec Machinery's Manufacturing System

Our expertise in mechanical design, control design, and software design, combined with our unique track record and experience and a wide range of technologies and skills, enables us to help customers solve their issues and problems.

We provide total solutions in terms of performance, cost, quality, safety, and production efficiency by responding directly to needs overseas.

We respond to customer needs with a consistent production system.

- 1.As a manufacturer of FA equipment for automation and labor-saving systems, we aim to develop unique products.

- 2.We pursue high performance, short delivery time and low cost through global and innovative management with an integrated production system for development, design and manufacturing (process, assembly, adjustment, installation).

- 3.We respond to increasingly sophisticated customer needs in the fields of assembly, measurement and testing, which are indispensable for innovation in advanced technologies.

Nidec Machinery is dedicated to technological innovation.

We have advanced manufacturing facilities and assembly and test operation spaces at our production bases in Japan and China.

We improve the reliability of our products by constantly procuring the most appropriate materials on a global basis according to the required specifications, and attain an even higher level of quality, low cost, and short delivery time by offering processed parts and small lot production in addition to standard products.

A group of professional engineers who cast 'dreams' into 'shape'

In recent years, technological innovation in the IT industry and economic growth in emerging countries have been remarkable.

In order to develop products in such an environment, "Professional group who has the customer's perspective" is essential.

We provide production solutions that make customers' dreams come true with passion to pursue our ideals and innovative ideas, while our engineers are fully committed to everything from development to manufacturing.

We will continue to aim to be a Think & Try Innovation Company in the field of production equipment by thinking from the customer's perspective.

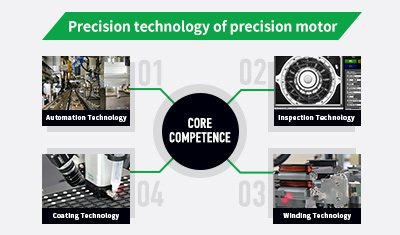

The 4 core competencies that support our Company

We have developed many production facilities, which have been supporting the production process of precision motors for a long time.

Based on this experience, we have carefully nurtured the 4 core competencies of "Automation, Inspection, Winding, and Coating Technologies." Leveraging these competencies, we offer specialized standard products, which are now used and well-received by many customers.

We are improving these technologies on a daily basis, not only in pursuit of performance and quality, but also in consideration of cost reduction to overcome global competition.

We will continue to evolve our existing technologies, while taking on challenges to create new core technologies.